Sustainability

Towards a more systematic approach to sustainability at every level of the company

There are numerous sustainability-related challenges facing businesses in the EU today, ranging from process efficiency and supply chain transparency to product emissions throughout their life cycle assessments.

As a group of companies, POLIPAKS has worked on implementing more environmentally friendly and resource-saving solutions—achieving several milestones of which we are genuinely proud. However, after being assessed for several years by Ecovadis (the world’s largest and most trusted business sustainability rating), we realized that our efforts are not enough to reach the desired targets. Current legislation and society’s active involvement demand a more systematic approach to everything we do in the realm of sustainability.

Our stakeholders are integral to our business and our future. We believe that transparent, data-driven, and goal-oriented dialogue can improve our efficiency and help reduce potential environmental harm.

In 2024, we initiated a project to identify and evaluate the company’s risks and strategic points related to sustainability. A Double Materiality Analysis (DMA) will serve as the foundation for our future plans and activities, providing us with a structured understanding of the most relevant environmental and social impacts, challenges, and required resources.

This journey presents a valuable business opportunity to collaborate with our partners and employees.

You will soon find the results of our DMA project here, along with the milestones of our future plans.

Environmental

Reducing our environmental impact through innovations, resource efficiency, and responsible decisions

Greenhouse Gas Emission(GHG) calculation

In 2024, we launched a project to identify and group the company’s risks and strategic priorities related to sustainability. GHG emission calculations will play a key role in supporting the Double Materiality Analysis (DMA), which will serve as the foundation for our future initiatives by providing essential data.

We have already made significant progress in our GHG calculation efforts, laying the cornerstone in 2023. Our goal is to transit from average product- and process-level emissions analysis to more specific product data in 2025 and 2026.

Since 2022, our ERP system has been collecting data for emissions measurements. In 2024, we further enhanced our emission control and management by integrating a Transportation Management System.

We not only evaluate and reduce footprint related to our production, but also work on Mobile Combustion Emission reduction since we have a large on- and non- road fleet.

Data and Technologies

Our group of company’s IT department is involved in every aspect of our business, providing the latest improvements, systems, and programs to ensure that our processes are safe, efficient, and optimized for resource consumption at all levels.

We are also improving our data collection and analysis by integrating advanced business intelligence tools in 2024. These tools, along with robust databases and record-keeping systems, offer deeper insights into our environmental impact and help us optimize our strategies.

Many of our production processes have been enhanced using smart technologies for better results, including:

Smart Plate Registration in Print

Intelligent Print Quality Control Cameras

Turbo Clean Technology in Extrusion

Optical Control System in Extrusion

Automated Laminating Adhesive Thickness Control

Electronic Color Tone Measurement and Control

Together with our data tracking systems, these innovations create opportunities for improved performance and sustainability across all our operations.

Pollution, Waste and Resource Management

Production site and warehouse

Production site and warehouse

Our production facility, established in 2015, was designed with a focus on best practices in energy efficiency and resource conservation. We continuously seek solutions to further automate our processes, reduce and reuse waste, and ensure efficient resource use while minimizing our environmental impact, all without compromising production capacity. We work exclusively with certified manufacturers and companies for all systems, vehicles, and equipment.

We use material and energy recovery processes and participate in reusable packaging flows.

VOC Regeneration System:

Our regenerative exhaust gas purification equipment uses an oxidation method (RTO) to purify solvent-based volatile organic compounds (VOCs) emitted from production equipment. The thermal energy generated during the process is sufficient to maintain optimal climate conditions for the facility throughout the year.

Solvent Recovery System:

This system recovers materials from ink/solvent waste mixtures in the printing process for reuse. Solvent regeneration minimizes environmental impact by recovering up to 95% of the solvent.

Re-granulation Technology (Inline/Offline):

Our re-granulation technology converts post-production PE waste back into granules for extrusion. The inline regranulation equipment ensures that materials compliant with legislation (direct contact with food) are returned to production.

Between 2016 and 2022, we implemented 7 projects to reduce natural gas consumption, which resulted in a more than 40% reduction in our gas procurement costs and volume since 2022

Thanks to electricity efficiency projects carried out between 2020 and 2022, our consumption decreased by 2%

Transportation and Vehicles

Transportation and vehicles

Since 2015, we have been dedicated to using only electric vehicles in our warehouses and production facilities. We operate around 30 electric machines that cover approximately 26,000 m² of production and warehouse areas, running 24/7.

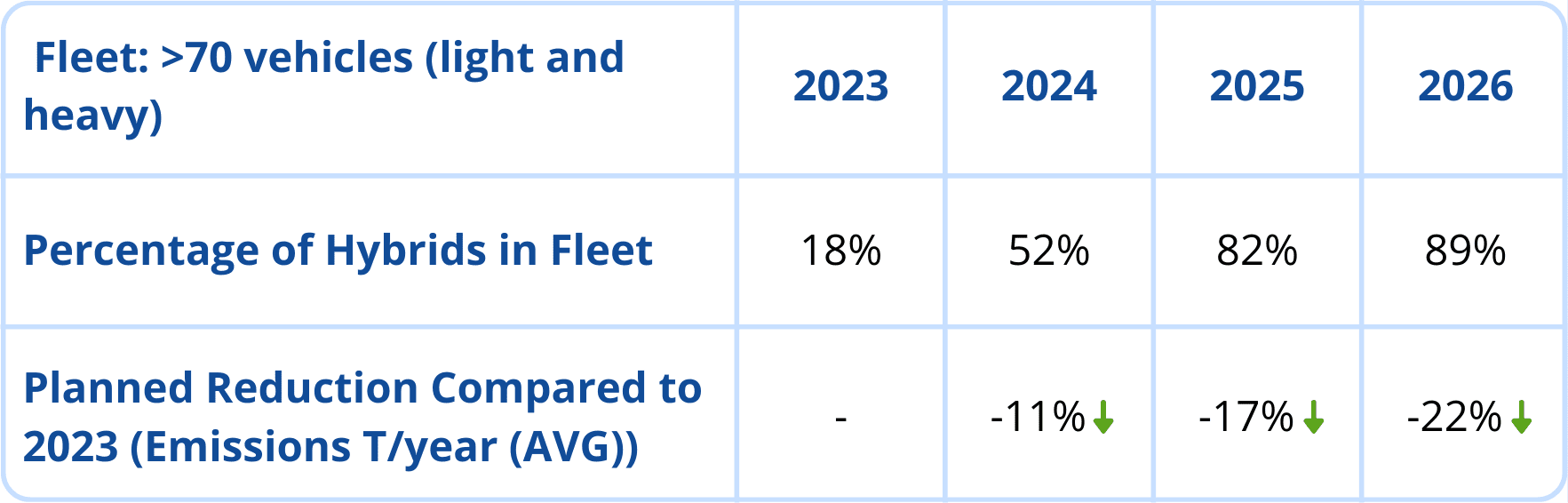

In 2024, our fleet consists of 52% hybrid vehicles, reflecting our ambitious plans for future emission reductions.

These initiatives, along with the omplementation of a Transportation Management System, underscore our commitment to sustainability and green practices. Additionally, we implemented a system to improve route optimization and reduce energy and fuel consumption.

Group of Company's Fleet Overview

Sustainable Product Targets

Sustainable Product Targets

We understand the environmental impact of our products and processes and we’re deeply committed to get precise data based targets to work on improvements. To support this, we have taken significant steps to transform our company’s environmental footprint into reliable data, starting with GHG emission analysis. In 2024, we are preparing our system to collect data for future Life Cycle Assessment (LCA) evaluations throughout its entire product life cycle – from raw material extraction to transport, disposal, or recycling. This will provide us a comprehensive framework for measuring the impact and making informed decisions.

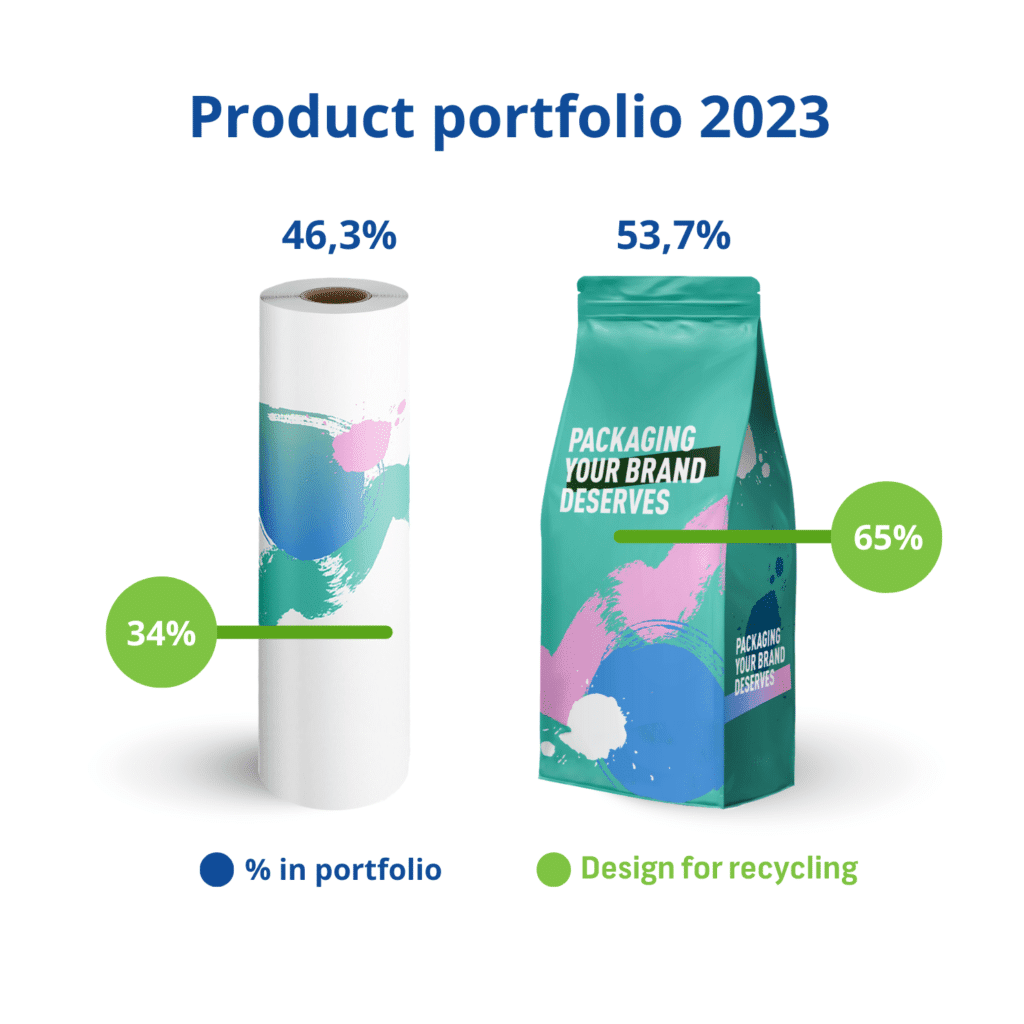

Our dedication to product safety and quality is reinforced through strict adherence to ISO and BRCGS standards. In product development, we prioritize Design for Recycling (D4R), ensuring that sustainability is at the core of our innovation. By leveraging our expertise, we are committed to helping clients transition to sustainable packaging solutions.

By 2023, almost 50% of the products in our portfolio were produced with PE and PP as the main polymers. These are potentially ready to be recyclable products with further detailed improvements. We stay up-to-date with changes in legislation and requirements to ensure we are ready for the next steps.

In 2024, we aim to achieve the target of 60% product transfer to mono-polymer materials. Additionally, 10% of our PE production scrap is returned back to production through material recovery. Increasing the proportion of PE in our production enhances material recovery rates, which positively impacts our CO2 footprint.

Energy recovery is also an integral part of our process, contributing to more efficient resource consumption.

We are working towards implementing recycled content in some of our products and closely monitoring technological developments and changes in product compliance.

Assessing the end-of-life impact of our products and waste is one of our key targets for 2025.

Human Capital

People are our greatest asset and one of the core values of POLIPAKS GROUP. In 2024, we employ over 450 specialists at various levels, with most based at our main office in Mārupe, Latvia, and branches in Estonia and Lithuania, as well as representatives in Austria and Spain. The majority work at our flexible packaging production site. Average length of service in the company – 6 years.

We are committed to providing a safe, modern, well-organized, and inclusive workplace where employees are empowered to grow professionally. To measure employee satisfaction and loyalty, we conduct an annual employee survey across the group, using the Employee Net Promoter Score (eNPS). This method helps gauge how likely employees are to recommend the company as a workplace and gives management insight into employee sentiment. Scores range from -100 to +100, with the target for POLIPAKS GROUP set at +20 or higher.

In connection with the risk and opportunity assessment of the company’s social and governance aspects, we conducted a targeted survey of our key stakeholders—employees in 2024. The main factors important to our employees were identified as social protection, adequate remuneration, and work-life balance. These will be the focus areas for the company’s upcoming tasks and priorities.

We value the honesty and suggestions from our colleagues and remain focused on improving working conditions, particularly for our technical, warehouse, and production staff.

Health and Safety

POLIPAKS GROUP identifies the significant impact of our activities, products, and services on employees and is committed to ensuring their health and safety. We understand our responsibility to maintain safe and accident-free operations at our production facilities while providing suitable working conditions that prevent workplace accidents and occupational diseases.

To achieve this, we focus on minimizing or eliminating harmful industrial factors and other occupational risks. Compliance with occupational health and safety (OHS) legislation is integral to our overall management system, ensuring business stability and contributing to the well-being of all employees.

Our commitment to upholding the highest safety standards includes:

- Adhering to Legal Requirements: We comply with national laws and OHS regulations.

- Regular Training and Inspections: Ongoing training programs and routine inspections ensure that our employees are equipped to maintain a safe work environment.

- Comprehensive Benefits: We provide benefits designed to enhance employee well-being and improve workplace safety.

- Continuous Improvement: We are dedicated to enhancing our occupational health and safety management system.

- Employee Involvement: Engaging employees in identifying hazards and reporting unsafe conditions is vital to our approach.

Our Objectives are to:

- Ensure employee safety during all work activities.

- Strive for zero workplace injuries and eliminate hazardous situations.

- Prevent the development of occupational diseases.

Through these efforts, POLIPAKS GROUP reinforces its commitment to creating a safe, healthy, and sustainable work environment for employees, interns, and visitors alike.

Human capital development

We work in three directions - our employee ongoing learning and development, input in society learning, and supporting different social activities.

Human Capital Development

At POLIPAKS GROUP, we see our employees as our most vital strength, and we’re committed to nurturing a culture that promotes ongoing learning and development. We provide an environment where your growth is prioritized, whether you work in production, the office, or warehouse operations.

How does it work?

- Ongoing Training & Development: From day one, we invest in your success. Our tailored training programs are designed to help you adapt quickly, build essential skills, and excel in your role. Whether you’re new to the company or transitioning to a new position, we’ll provide the guidance and support you need to thrive.

- Skill Advancement: At POLIPAKS GROUP, we are committed to developing not just job-specific skills but also leadership capabilities, emotional intelligence, and personal effectiveness. We prioritize helping our employees grow in these areas, along with enhancing their digital skills to succeed in an ever-evolving technological landscape. In 2023, our employees together spent over 2,000 hours in learning and development activities, and in 2024, we’ve already surpassed 1,000 hours of training. Individual growth is our priority, and will directly reflect in career progression.

- Personal and Professional Growth: We provide continuous learning opportunities, from workshops and mentorship to training on advanced production techniques or professional development in the office. Our commitment to your growth ensures you are well-prepared for the next step in your career.

- Supportive Work Environment: At POLIPAKS, we’re proud of our collaborative culture. You’ll have the chance to work alongside experienced mentors and colleagues who are eager to share their knowledge and help you succeed.

Explore our current job opportunities and discover how POLIPAKS GROUP can help you build a rewarding future! Link to actual vacancies!

Social Responsibility

For years, we have successfully collaborated with local educational institutions, regularly providing students with excursions and practical experience. This is part of our social and corporate responsibility. Our goal is to inspire young individuals, encouraging them to consider building their careers here, particularly in the production sector, and to hopefully welcome some of them as future colleagues.

All actual initiatives you can follow in our Linkedin profile

Social Activities

Our group has decided to support local initiatives in the Mārupe District, where our main office and production site are located. Our focus is primarily on sponsoring activities related to sports and children and education using our products as part of the sponsorship.

Supply Chain Labor Standards

We are planning to develop supply chain communication that aligns with the latest legislation and our commitment to sustainability goals. This initiative aims to ensure that labor standards across our supply chain meet the highest ethical and legal requirements, reinforcing our dedication to responsible and sustainable practices at every stage of our business.

Privacy & Data Security

All our activities and documentation are carried out in accordance with GDPR,EU and local legislation and supported by our IT department, ensuring data safety and privacy.

GOVERNANCE

The governance structure at POLIPAKS GROUP is implemented in accordance with best practices, upholding transparency principles and ensuring a balance of stakeholder interests.

Board Diversity and

Ownership

Board diversity and ownership

More about our company history, ownership and business structure can read here

Business Ethics

We are currently working on the Code of Ethics and developing our Ethics framework based on various internal standards that we have now. Our goal for 2025 is to refine and enhance this documentation by consolidating it into a unified Code of Ethics. This will provide even clearer principles and rules for fair and responsible business practices within the POLIPAKS GROUP.

Anti-corruption Practices

Business management operates within the framework of all applicable legislation—both EU and local. We regularly provide employee training on the fundamental principles of the business environment, including corruption risks and business ethics. A survey conducted in 2024 revealed that most of our employees view these principles as crucial for positively evaluating the company as a trusted workplace.

Tax Transparency

Our company is committed to tax transparency, ensuring that all taxes owed are accurately reported and paid in full in the jurisdictions where we operate. This commitment reflects our dedication to ethical business practices and reinforces our reputation as a responsible corporate citizen, contributing to the communities we serve. By fostering transparency, we demonstrate our accountability and support for a fair and sustainable business environment.

Social

POLIPAKS GROUP prioritizes a safe, inclusive workplace that values employee growth, satisfaction, and social responsibility through ongoing development, health and safety initiatives, and community engagement