About

Polipaks sets its target at providing a full packaging solution to the customer. As a full-cycle producer, we buy plastics in granules and sell ready-made printed bags and rolls. Our sales team will analyze every enquiry and work out the best possible solution bringing together the customer request and our technological skill and capabilities.

Each of our customers has a dedicated personal account manager from the customer service team who takes the full care of all production steps starting from design preparation and approval with our in-house design studio and finalizing the product with an on-time delivery to the client’s address.

Story

We are currently certified under ISO 9000 and BRC packaging standards, which guarantees our compliance with all of the hygiene and safety regulations and allows us to work with the most demanding European producers of food and non-food products.

Awards

1st Place Online Voters Award in Best Latvian Packaging Contest (WPO Member)

More

22.11.2018

Award for the creative, innovative and high quality solution for the Quadseal packaging product

More

22.11.2018

"Latvians conquering the seas"

Latvian contest nominee

More

29.03.2017

"Fast growing manufacturer" award by the local authority of Marupe

More

19.10.2018

Our Milestones

With our recent equipment upgrade and new installations in the extrusion and bag making departments, we have reached and exceeded the round record capacity for the monthly production.

In April 2016 our packaging production plant was certified in accordance with the BRC (British Retail Consortium) Global Standard for PACKAGING AND PACKAGING MATERIALS (2015) receiving the highest category – AA.

- During 2012-2015 POLIPAKS and its subsidiary company POLIPAKS NT and with the support from the Investment and Development Agency of Latvia, began constructing a new modern production and logistics centre, with a total area of 35,000 m2 in Marupe a suburb of Riga, a 10 minutes’ drive from Riga Airport.

- Installation of modern European equipment, which allowed to double production capacity of the plant.

- Launch of the W&H 9-layer barrier extrusion line.

In 2012 the Production Quality Management System of the company was certified in accordance with the ISO 9001-2008 standard.

- Mastering the production technology of FLEXO HD printing plates

- Launch of the W&H multilayer barrier extrusion line

Since 2009 our printing capabilities have expanded we can now offer our Customers 10 colour, large format printing and lamination.

Launch of lamination

We have updated our production facilities by installing the latest manufacturing equipment, this was supplied by European Companies who specialise in flexographic and peripheral technologies.

The first 6-colour flexographic printing line with central cylinder

We started working with flexographic printing, since then we have been developing and expanding our technological capabilities and the range of products and services we can offer to our Customers.

POLIPAKS was founded as a manufacturer of packaging materials. Since then our experience has grown year on year in polymer film extrusion and the production of many different packaging products using these films.

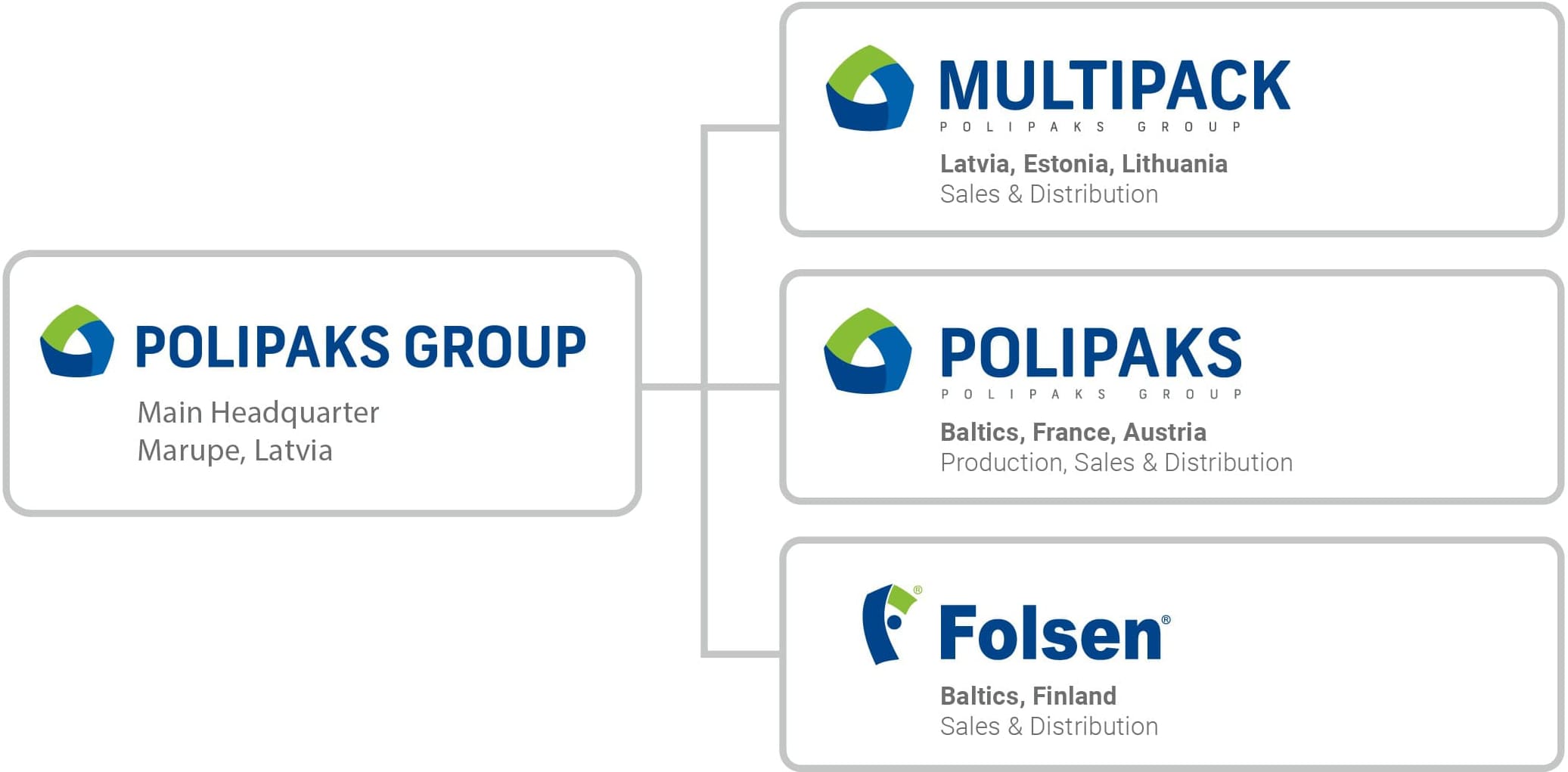

Corporate Structure

Polipaks Group

Polipaks factory is the largest manufacturing member of Polipaks Group, which comprises two production companies and three distribution companies with offices in four countries. Our group focuses on providing the end Customer with a full solution in rigid, flexible packaging and adhesive tapes. The distribution network created by our trading companies covers Customers in more than 30 different countries.

The main production site of flexible packaging of Polipaks Group is in Riga, Latvia, where the most technologically advanced and complex products are being designed and produced. Polipaks has also its own sales team covering most of Europe.

Polipaks Group has its own representative headquarters in Latvia, Estonia and Lithuania.

Multipack plays a key role as a supplier of packaging solutions and high-quality adhesive tapes to product manufacturers, retailers, hotels, restaurants, cafes and many other business industries in the Baltics.

Polipaks Group is a structured and well-organized business that is constantly developing and actively expanding. The total turnover of Polipaks Group in 2023 exceeded 74 mln EUR and we expect our growth rate to be increasing in the future.